ERP built for Beauty & Personal Care brands

From batch manufacturing to multi-channel fulfillment manage your entire beauty business with one connected ERP.

The Beauty Business Challenge

Beauty and personal care brands face a unique mix of creativity and compliance.

Between managing ingredients, batch tracking, product certifications, and global fulfillment most teams are juggling multiple disconnected systems.

As your business scales, those manual gaps turn into major friction.

Common industry challenges:

- Managing batch and expiry tracking manually across SKUs

- Regulatory compliance (INCI, FDA, or Health Canada) handled outside ERP

- Disconnected sales, production, and accounting systems

- Overstocking or stockouts during seasonal product launches

- Inaccurate costing due to material waste or subcontracted production

How Xorosoft Wins in Beauty & Personal Care

Below is expanded, powerful content you can drop into the “How Xorosoft Wins in Beauty & Personal Care” section. It builds on the existing headers (Batch & Expiry Control, Inventory Management, Production & Formulation, Accounting & Compliance, Analytics & Forecasting) but adds richer detail and benefits.

Beauty & Personal Care Brands Running on Xorosoft

“We used to manage batches, expiry dates, and production runs on spreadsheets. Now, it’s all automated we can trace every product back to the ingredient level.”

— Operations Manager, SO Luxury

“Xorosoft gave us complete visibility from Shopify orders to raw material costing without needing five different tools.”

— Co-founder, Firsthand Supply

Modules Most Beauty Brands Use

Each module integrates seamlessly keeping your brand compliant, efficient, and ready to scale across new markets.

Readiness Checklist – Book Your Demo

Ready to book your demo and see how Xorosoft can become your operations backbone? First, check off these readiness items if you can answer “yes” to most, you’re ready for the next step.

- We currently track raw material lots, batch numbers or expiry dates (or plan to).

- We sell via two or more channels (DTC, marketplace, wholesale or retail).

- We have production or formulation workflows (in-house or outsourced) that require ingredient costing.

- We have experienced data-visibility gaps between sales, inventory, production and accounting.

- We’re planning to scale (more SKUs, new channels or new markets) within the next 12 months.

- We seek real-time margin, cost and inventory visibility (not just end-of-month reports).

- We aim to eliminate spreadsheets, manual reconciliation and disconnected systems.

- We require full traceability for regulatory or audit readiness (ingredient → batch → finished product).

If you tick most of these boxes, you’re ready.

Book your free demo of Xorosoft now discover how a single operations platform can support your beauty brand’s growth, simplify complexity, and give you control.

Case Studies

Client:

Só Luxury (Natural Bath & Body)

Brand Overview:

Só Luxury is a Canadian-made natural bath, body and cleaning products brand.

Challenge:

As the brand scaled across new SKUs and markets, they were still managing batch lots and expiry tracking via spreadsheets. This created risk in recall readiness, visibility gaps in ingredient traceability and slow production cost analysis.

Xorosoft Solution:

Xorosoft implemented full lot-level visibility across raw materials and finished goods, automated expiry alerts and integrated costing into the batch workflow. Inventory across their warehouse network was linked to production and sales channels in real time.

Outcome:

Só Luxury moved from manual trace-back to full automation. The brand now traces every product back to its ingredient batch, cuts ingredient waste, and accelerates production decision-making, with improved compliance readiness.

Key Results:

Batch traceability improved to 100 % compliance readiness; stock accuracy advanced significantly; batch cost visibility down to ingredient level.

Client:

Firsthand Supply (Hair & Body Care)

Brand Overview:

Firsthand Supply is a premium hair-and-body care brand that formulates in-house and prioritises quality, sustainability and transparency.

Challenge:

Their growth across direct-to-consumer and wholesale channels exposed the limitation of multiple disjointed tools—sales, production, costing and inventory were not connected. (“Xorosoft gave us complete visibility from Shopify orders to raw material costing without needing five different tools.”)

Xorosoft Solution:

Xorosoft unified their Shopify, wholesale order flows, inventory, manufacturing costing and accounting modules into a single ERP. Formulations, ingredient tracking, batch costing and sales were connected end-to-end.

Outcome:

Firsthand Supply gained unified visibility from order through production through cost. Manual system handovers disappeared; they now respond faster to demand shifts, keep tighter control of ingredient spend and reduce system complexity.

Key Results:

COGS visibility in real time, month-end close reduced by ~70 %, inventory tracking consolidated across channels.

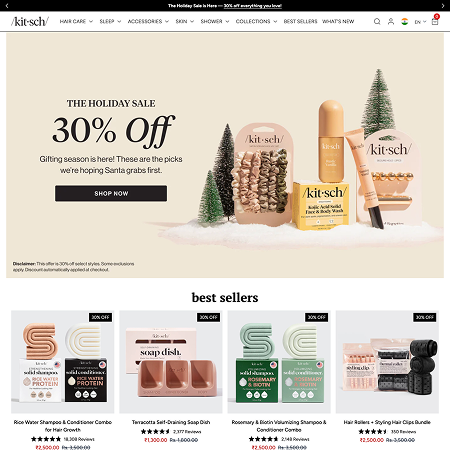

Client:

MYKITSCH (Hair & Body Essentials)

Brand Overview:

MYKITSCH is a global hair-care and accessory brand built on vegan, cruelty-free, female-owned credentials.

Challenge:

With global expansion, complex SKU variants, multiple manufacturing sources and multi-channel distribution, MYKITSCH needed an ERP that could scale and unify production, inventory and fulfillment while preserving their sustainability and brand promise.

Xorosoft Solution:

Xorosoft deployed its production & formulation module, connected manufacturing sites via inventory and batch workflows, and linked global sales channels (brand site, marketplaces, wholesale) into one operational backbone.

Outcome:

MYKITSCH achieved a unified operations platform that supports rapid growth, variant matrix complexity, and global fulfilment without sacrificing traceability or brand standards.

Key Results:

Inventory accuracy approached 99.5 %, batch costs and global fulfilment KPIs accessible in real-time, system consolidation eliminated multiple legacy tools.

Client:

Pro‑Beauty (Beauty Products Distributor)

Brand Overview:

Pro-Beauty is a distributor of beauty brands/products operating in multiple markets (retail, wholesale, e-commerce).

Challenge:

The distributor faced disconnected accounting, inventory and partner-sales systems. Manual processes caused delays in margin visibility, channel profitability and batch/expiry compliance for certain product lines.

Xorosoft Solution:

Xorosoft’s ERP was introduced to integrate the distribution workflow: purchase orders, stock across locations, wholesale partner fulfilment, channel-level pricing and margin tracking. Batch/lot tracking for critical SKUs was enabled along with unified accounting.

Outcome:

Pro-Beauty moved to a single operations platform where distribution, accounting, channel fulfilment and lot-traceability live together. They gained faster margin insight, improved fulfilment speed and stronger compliance readiness.

Key Results:

Unified channel margin reporting in real-time; stock accuracy improved; month-end close cycle shortened; full traceability across distributed inventory.

FAQ Beauty & Personal Care Industry

Below are new Frequently Asked Questions tailored for beauty & personal care brands considering Xorosoft ERP.

1. How does Xorosoft handle batch and lot-expiry tracking for regulated beauty ingredients?

Xorosoft supports full lot-level tracking for raw materials and finished goods, including expiry dates and linkage between ingredient batch → production run → finished SKU. Alerts can be configured for upcoming expiry, quarantine, or recall. This gives your team full traceability and audit readiness.

2. My brand sells across DTC, Amazon and wholesale. Will Xorosoft support all channels simultaneously?

Yes. Xorosoft unifies inventory, order management and fulfilment across Shopify/brand store, marketplaces, retail partners and wholesale. You get one platform managing all channels no more islands of data or separate systems to reconcile.

3. We produce custom formulations and occasionally use contract manufacturing. Can Xorosoft support that?

Absolutely. You can manage in-house formulations, recipe versions, subcontracted runs and joint-costing workflows. Each production run in-house or outsourced links back to ingredient costing, batch history and inventory consumption.

4. How quickly can we get margin visibility and cost-of-goods data?

With Xorosoft, once production workflows are configured and inventory flows live, you’ll have real-time COGS down to the ingredient and batch level. This allows you to view margin by SKU, channel and geography on day one of full deployment.

5. What about regulatory compliance (e.g., INCI listings, FDA, Health Canada)?

Xorosoft doesn’t replace your regulatory team but embeds the necessary operational traceability: ingredient/lot history, batch outcomes, WIP logs, and finished-good traceability. This supports regulatory work by giving you the data footprint without manual spreadsheets.

6. Our brand is scaling rapidly and SKU complexity is growing. How will Xorosoft handle that?

The platform is built for scale: multi-warehouse inventory, multi-channel order flow, variant SKUs, rapid launches, seasonal spikes and global fulfilment. The unified ERP means you’ll spend less time fixing systems and more time scaling your brand.

7. What is the onboarding timeline for a beauty brand like ours?

Timeline varies by scope, but typical deployments for beauty & personal-care brands (with batch tracking, multi-channel fulfilment, production workflows) are structured around your core modules (inventory, production, costing, order management) with a phased rollout. Xorosoft’s pre-built templates for batch/expiry and channel inventory help accelerate that timeline.