XoroONE

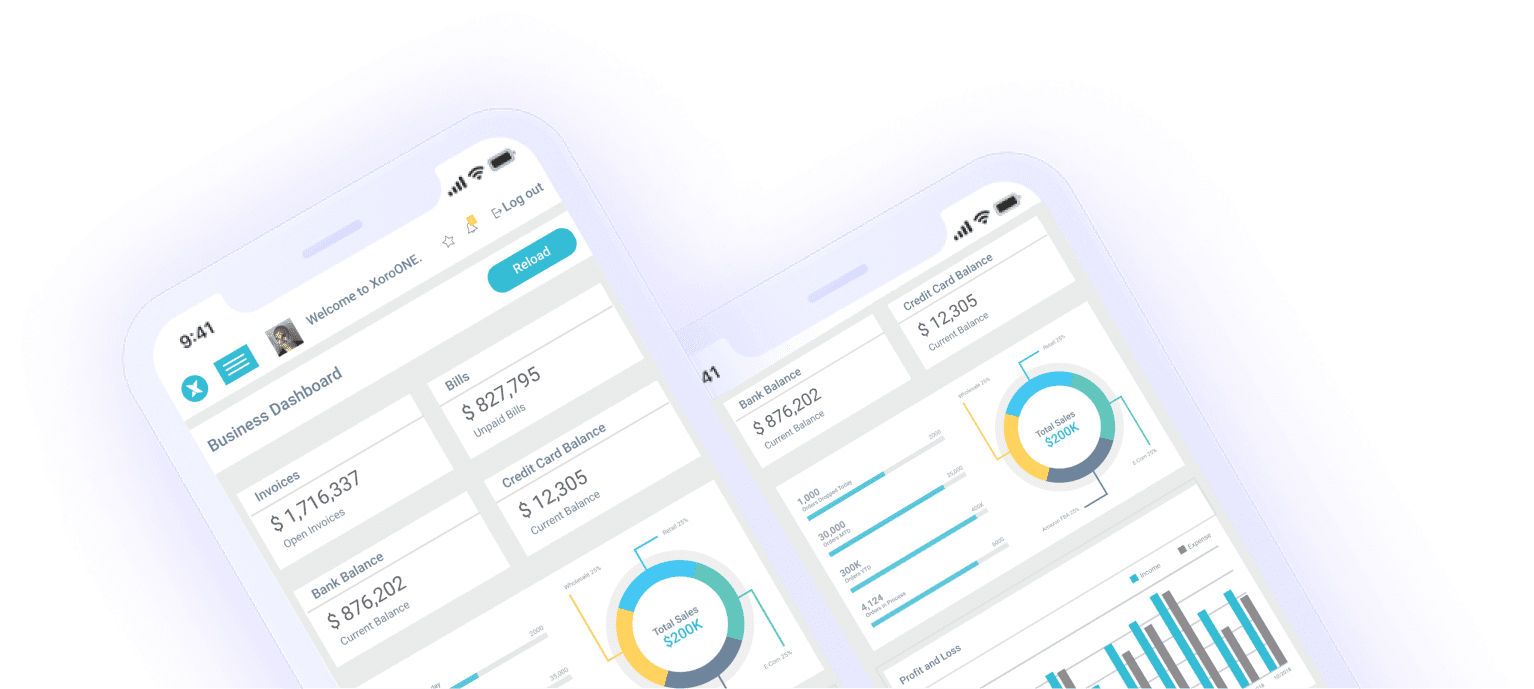

XoroONE is a cloud-based ERP system for retailers, wholesalers, and manufacturers. Enjoy features such as omnichannel connectivity, sophisticated inventory controls, full accounting suite, warehouse management, production & manufacturing modules, business reporting and more.

Our Clients

FEATURES THAT WILL STREAMLINE YOUR BUSINESS

XoroOne Features

Forming strong and

trusted connections with our clients

0+

Customers

0+

Team Members

0+

Years Of Experience

0+

ERP & Related Solutions

Excellent team!!!

Seamless Shopify Integration!

Great $$ value

Best WMS in the Market!!

Really Great experience!

Best ERP Software!!

Reliable and Affordable!

Best ERP Selection we could have made...

Essential

$499

$449

$499

Basic ERP functionality for anew business

Standard

$799

$719

$799

Added users & locations for a growing companyPremium

$1299

$1169

$1299

Premium features for your established companyWe integrate with the leading sales channels, marketplaces and services

so you won’t need to compromise on your technology stack.

World Class Integrations

E-Comm Integrations

Order Portals & EDI

Shipping Platforms & 3PLs

Payment Processing and Integrations Platforms

Learn more about Xorosoft

TALK TO ONE OF OUR CONSULTANTS TODAY!

Call us: 1-888-406-XORO (9676)